Befukting og fuktighetsregulering for konserthus og orgler

Store pipeorgler i konserthus og kirker må opprettholde luftfuktigheten i orgelkamrene for å bevare dimensjonene til lydplankene og glidebryterne i tre.

Hvis luften i orgelkammeret blir tørr, vil den suge fuktighet fra det treet omkring og føre til at det forandrer seg. Dette kan føre til at glidebryterne vrir seg og setter seg fast, noe som fører til et instrument som ikke reagerer. Hvis lydplankene endrer form, vil ikke luften resonere riktig, og orgelet blir ustemt.

Når det opprettholdes en relativ fuktighet på 55 % i orgelkammeret, er treet i likevekt med luften, og det opprettholder fuktighetsinnholdet og formen.

Dette oppnår man ofte med dampbefuktere med liten kapasitet som mater lave nivåer med damp inn i et orgelkammer, enten direkte gjennom en vifte eller via et damprør.

I tillegg til orgelkammeret krever hovedauditoriet og sceneområdet i et konserthus også fuktighetsregulering. Tremøbler og tregulv samt musikerenes instrumenter krever en relativ luftfuktighet på rundt 50 %.

I sceneområdet må også fuktigheten opprettholdes for å gi optimale forhold for stemmen til sangerne. Hvis atmosfæren er for tørr, vil det gå ut over stemmen da sangerens nese og hals er tørr.

Fordelene med Condair befukting i konserthus og orgler er:

- Omfattende erfaring verden over med mange konserthusprosjekter

- Omfattende produktspekter som oppfyller kundenes behov

- Evne til å tilby innovative tilpassede løsninger for uvanlige bruksområder

- Lavenergisystemer som reduserer driftskostnadene og forbedrer fuktighetsreguleringen

- Løsninger som krever lite vedlikehold reduserer behovet for løpende service

- Omfattende service med råd, design, levering, installasjon, igangkjøring, vedlikehold og levering av reservedeler direkte fra produsenten

- Royal Albert Hall, Storbritannia

- Sydney Opera House, Australia

- Alexandra Palace, Storbritannia

- The Royal Opera House, Storbritannia

- Opera North's Howard Assembly Room

- Christ's Hospital school, Storbritannia

Andre områder hvor Condair leverer viktig fuktighetsregulering

Eliminere statisk elektrisitet med befukting

En relativ fuktighet på 45-55 % eliminerer oppbygging av statisk elektrisitet i produksjonsmiljøer.

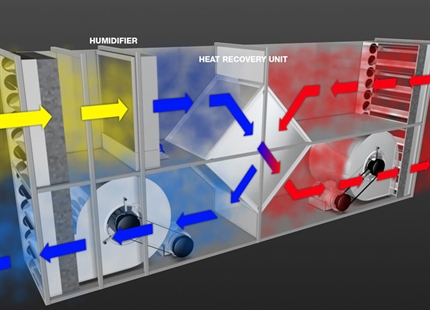

Les merKanalmonterte evaporative kjølestrategier

De tre viktigste AHU evaporative kjølestrategiene forklart, dekker direkte, indirekte og kjøling av avtrekksluft.

Les merBefukting for museer, gallerier, kunst og antikviteter

Bevaring av kunstverk og antikviteter og tilhørende utstyr.

Les merBefukting av datasenter

Gir høy kapasitets evaporativ kjøling til lav pris og bekjemper ESD.

Les merBefukting av kontorer

Forbedrer personalets helse og produktivitet og reduserer fraværet.

Les merBefukting for sykehus og helsevesen

For rekonvalesens og beskyttelse av pasienters helse.

Les merBefukting hjemme

Forbedrer helsen og beskytter møbler, gulv og tekstiler.

Les merBefukting av teproduksjonteproduksjon

Befukting under fermentering øker oksidasjonen og kvaliteten og verdien på svart te.

Les merBefukting av eggklekkeri

Kritisk for maksimalt utbytte av kyllinger fra hvert parti.

Les merBefukting ved soppdyrking

Gir optimale vekstforhold og reduserer skader på soppen.

Les mer